How to Choose the Right Stainless Steel Grade for Different Industries

August 17, 2025

Mastering Stainless Steel Cutting and Forming: Create Professional-Grade Workpieces

August 17, 2025

Water Jet technology is an innovative cutting method that uses high-pressure water to create smooth, precise cuts. It can process a wide variety of materials and is widely adopted across different industries for its accuracy, flexibility, and clean performance. This article explores the key features, working principles, and best practices for using Water Jet technology to maximize efficiency in production processes.

Key Features of Water Jet Technology

1 Cold Cutting Process – Water Jet uses only high-pressure water to cut materials without generating heat. This eliminates the risk of chemical reactions or thermal distortion.

2 Versatility – It can cut a wide range of materials, including metals, stainless steel, aluminum, stone, glass, and plastics, without heat-related damage.

3 High Precision – Water Jet offers excellent cutting accuracy, making it suitable for complex shapes and detailed designs without the need for secondary tools.

4 Clean and Eco-Friendly – The process produces no hazardous gases or chemicals, making it safe for both operators and the environment.

5 Multi-Industry Applications – Water Jet is used in sectors such as machinery manufacturing, construction, and advanced component production.

How Water Jet Works

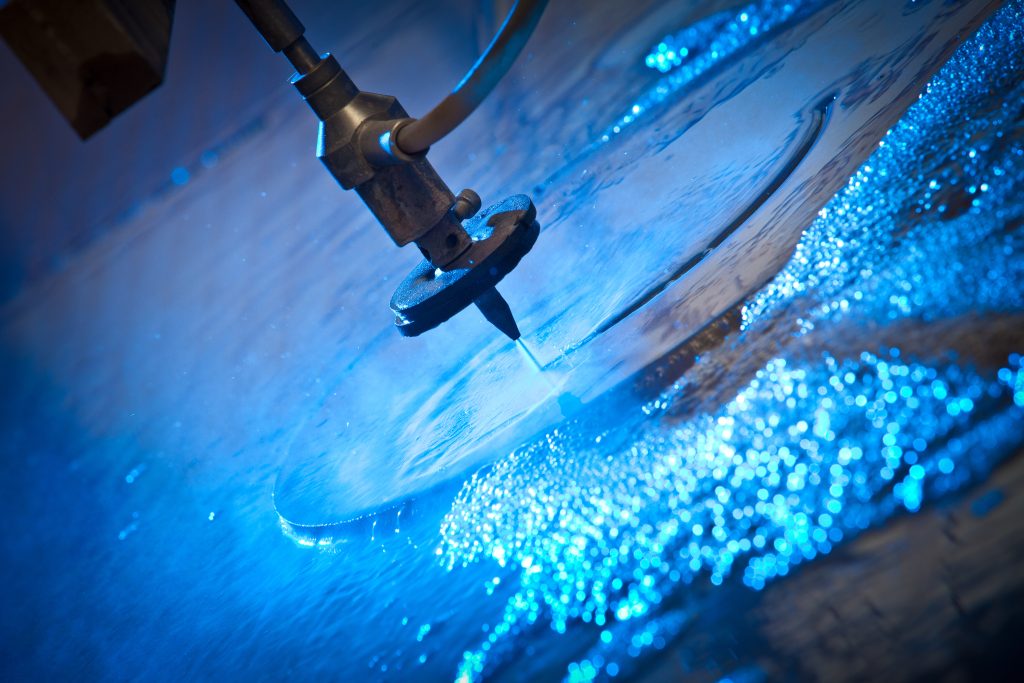

The process starts with a high-pressure pump that generates water pressure between 60,000 and 90,000 PSI. The water is forced through a fine nozzle, typically around 0.2 mm, reaching speeds up to three times the speed of sound. This stream can cut through various materials without heat damage. For harder materials like thick metals or stone, abrasive substances such as aluminum oxide or silica can be added to the water stream for more powerful cutting. The entire process is controlled by CNC (Computer Numerical Control) systems, which ensure precision, repeatability, and the ability to produce complex designs.

Best Practices for Effective Water Jet Cutting

To maximize the benefits of Water Jet technology, proper usage and maintenance are essential. Key practices include:

Selecting the Right Nozzle – Standard nozzles work for general materials like metals and plastics, while abrasive nozzles are better for hard materials such as stone or ceramics.

Adjusting Water Pressure – Softer or brittle materials require lower pressure, while harder materials need higher pressure for smooth cutting.

Controlling Nozzle Distance – Maintaining an optimal distance of 2–3 mm from the surface improves accuracy and prevents backflow that can reduce cut quality.

Using Quality Abrasives – High-grade abrasives prevent nozzle clogging and improve cutting performance. Proper storage is also important to avoid moisture issues.

Leveraging CAD/CAM Software – Designing with CAD/CAM helps optimize cutting paths, reduce errors, and adapt speed to material thickness and complexity.

Regular Machine Maintenance – Cleaning filters, checking high-pressure pumps, inspecting hoses, and replacing worn parts like seals and nozzles on schedule reduces downtime and extends machine life.

E.I.S Water Jet Services

E.I.S provides high-quality custom production using advanced Water Jet technology. Our process delivers clean, smooth edges without heat distortion, supporting industries such as automotive, aerospace, and architecture. With professional expertise and state-of-the-art equipment, we ensure precise and efficient results for every project.

Conclusion

Water Jet technology is a highly flexible and efficient cutting solution that enhances productivity and competitiveness across industries. With its cold-cutting capability, wide material compatibility, precision, and eco-friendly operation, Water Jet has become a key contributor to industrial success today.